Water-Water everywhere....

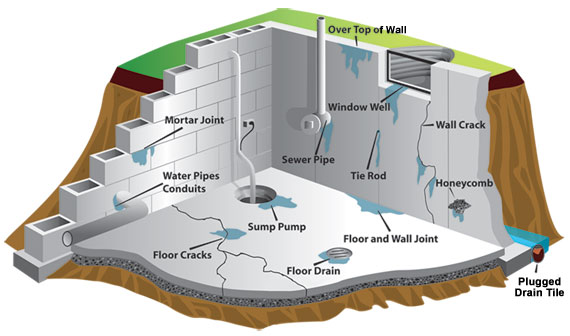

Water-Water everywhere....Most damage to buildings is caused by Dampness and the penetration of moisture into the building's structure. Coating and Foaming In cprovides clients with services that include internal and external waterproofing, using the latest techniques. All these techniques are environment friendly, safe for the applicator as well as for the building, hygenic, easy to apply and highly cost-efficient. C & F Inc Incalso makes available services to prevent as well as treat water leakage.

Our treatment starts directly over the RCC slab with laying over our polymerised waterproof brickbat coba to provide necessary gradient of 1 in 120 (1 inch in 10 ft.) for the easy flowaway of rainwater. Finally the brickbat coba is covered with our C & F Polymer jointless waterproof plaster finished smooth with trowel in cement colour, marked into 300 mm (1 ft.) false squares. This treatment is carried along the inner side of parapet and/or other adjoining wall upto a height of about 300 mm(1 ft) in the shape of a round vata. The average thickness of this treatment is about 100 mm (4 in) with a minimum thickness at water outlets being 75 mm (3 in). This surface is hard and tough, and suitable for all normal domestic activities.

In the case of existing basements or any other underground structures where there is no access available from the outside and below the raft slab, we treat from inside with our injection C & F Grouting and polymer box methods.

The treatment starts with giving injections into the structure, as and where found necessary by us. Thereafter, our waterproof later, finished smooth with trowel in cement, is laid on the floor and continued on the side and partition walls, columns etc. for their full height or 300 mm (1 ft) above ground or other adjoining apron level. the average thickness of this treatment is about 65 mm (21/2 in) on the floor and 25 mm (1 in) on the walls.

|

After the plumbing work is completed and the normal plaster to the outer surface is provided by the owners through the main contractor, the treatment starts with giving injections into the structure , as and where found necessary by us. There after our C & F waterproof layer, finished smooth with trowel in cement,is laid on the floor and continued on the side and partition walls upto their full height. The average thickness of this treatment is 65 mm(21/2 in) on the floor and 25 mm (1 in) on the walls.

The treatment starts with giving injections wherever we find necessary in-between the joints of RCC beams, columns, pardi and brickwork, to fill up the gap and joint. Then the surface is covered with out special C & F water proof plaster in three coats finished in sand faced texture. The average thickness of this treatment is about 25 mm (1 in)

Before our work is started, all cutting or chasing in the floor and/or walls, and all the plumbing work should be completed by the plumber and the normal plaster to the ceiling and the upper part of walls provided by the owners through the main contractor.

First we fill in the depressed or sunk portions of the WCs and Bathrooms, etc with our brickbat coba with necessary gradient for the easy flow away of water towards the nahani trap or soil pan, the surface being finished suitably with 18mm (3/4 in) thick C & F waterproof plaster, in order to receive tiles to be laid by the owners. The said C & F waterproof plaster shall then be continued on the walls above the floor for a height of 1 metre (31/4 ft). In the shower area of the bathrooms, the treatment shall be for the full height of the walls.

The treatment starts with giving injections into the structure as and where found necessary by us. Thereafter the entire surface will be covered with our C & F Polygunite waterproof layer using guniting process (with or without IRC fabric or reinforcement as the case may be).

Finally the surface will be finished either smooth, or in sand-faced texture, or rough if it is desired to be covered with decorative tiles as the case may be.

The average thickness of this treatment is about 50 mm (2 in) on the floor and 35 mm (11/4) on the walls.

NOTE: We also offer non conventional treatments based on Modified Polymers Epoxies, Poly-urethanes, FRP Etc.